Description

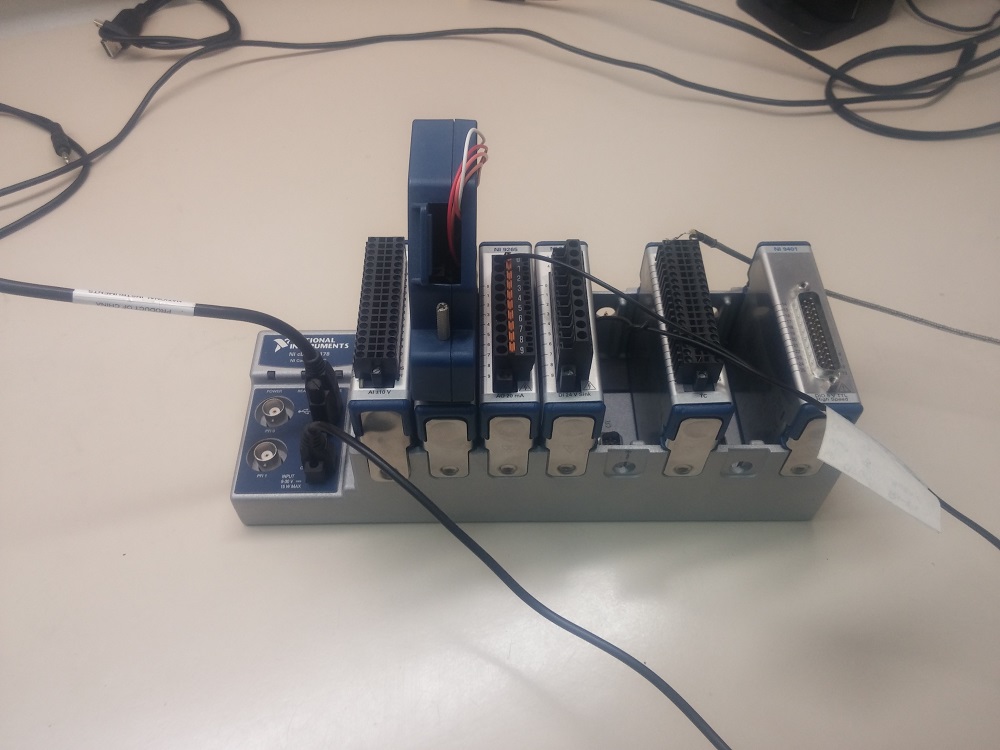

In this project, an NI CompactDAQ Chassis with four slots was utilized (NI cDAQ USB-9174). The slots were filled with the following modules:

NI-9205 – 32 channels of analog input.

NI-9264 – 16 channels of analog output

NI-9211 – 4 channels of thermocouples

NI-9203 – 8 channels of 4mA-20mA current values.

The analog input channels were used to read a variety of sensors such as temperature sensors (thermistors), pressure sensors, hall sensors (to read engine positions and velocities), as well as other sensors.

The analog output module operated the different devices, such as the stepper motor that was used as a scanner, a pump that was used to chill the system, and a heater that was used to heat the system. The heater was operated by pulse width modulation (PWM) and worked in the PID mode, according to the thermistor (temperature) sensors.

Another engine was operated at different velocities, according to a linear operation profile. A hall sensor that measured the engine velocity was used to sample the real engine velocity and, according to the set-point velocity, was applied to vie the analog output voltage. An additional analog output module was used as a binary button to enable/disable the configuration.

Ambient temperature values were acquired with a thermocouple module at different locations in the system. The current module was used to acquire signals from the vibration sensor (for safety uses) and a calibrated pressure sensor in order to calibrate the internal pressure sensors.

ReadyDAQ customized the order to meet the customer’s requirements, and since the software application was not built from scratch the software was delivered very fast and on a reasonable budget.

- Date Published: 06/22/2016

- Categories: Computerized control and command software setup utilizing LabVIEW

Example projects

Developing a Product Lifetime Setup for an Aesthetic Device

Computerized control and command software setup utilizing LabVIEW

Developing a Product Lifetime Setup for an Aesthetic Device

Computerized control and command software setup utilizing LabVIEW

Developing a Prototype to Operate a Carbon Fiber Based Heater

Computerized control and command software setup utilizing LabVIEW

Developing a Heat Engine for a Prototype

Computerized control and command software setup utilizing LabVIEWLatest From Blog

Engineers turn to automated test equipment to save time

With engineers rushing tests in order to hit tight product deadlines, the market for test equipment that automatically detects faults in semiconductors and other

ENGINEERS TURN TO AUTOMATED TEST EQUIPMENT TO SAVE TIME

With engineers rushing tests in order to hit tight product deadlines, the market for test equipment that automatically detects faults in semiconductors and other

Semiconductor Testing

Automated test equipment (ATE) is a computer-controlled test and measurement equipment that allows for testing with minimal human interaction. The tested devices are referred