Home / DEVELOPING A PROTOTYPE TO OPERATE A CARBON FIBER BASED HEATER

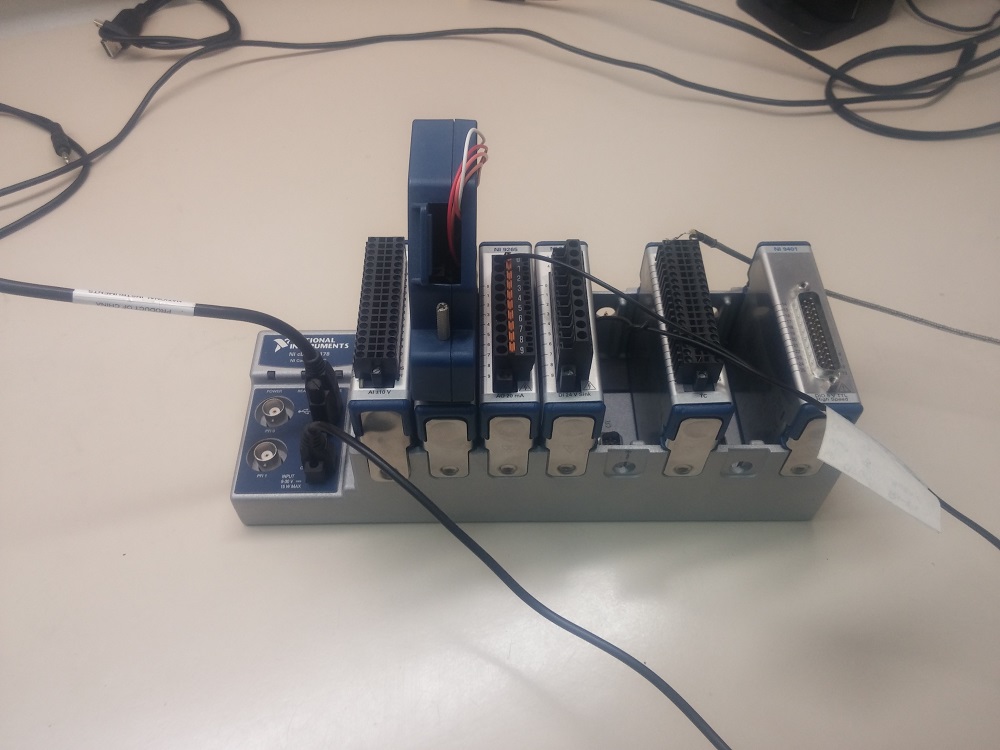

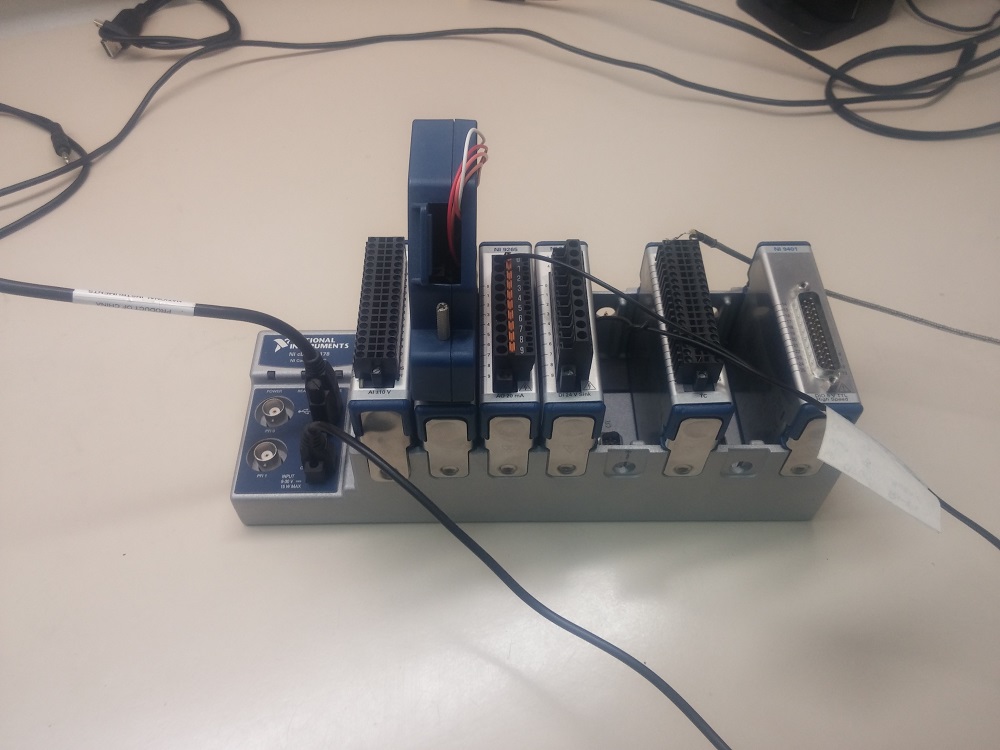

In this project an NI CompactDaq chassis with 8 slots was used (NI cDAQ-9178), however only five modules were used:

The slots were filled with the following modules:

NI-9208 – 16 channels of 4mA-20mA analog input current values.

NI-9265 – 4 channels of 4mA-20mA analog output current values.

NI-9421 – 8 channels of 24V digital input

NI-9401 – 8 channels of high speed digital input and output

NI-9213 – 16 channels of 24bit thermocouples

The current analog outputs were operated with PWM, and controlled with an SCR, that operated a heater.

The thermocouple module was used to measure the temperature at different points in the system and worked in a PID mode.

The digital output and input was used to operate other devices and to synchronize other components in the system, as well as to sense digital switches in the system.

ReadyDAQ customized the order to meet the customer’s requirements, and since the software application was not build from scratch the software was delivered very fast and in reasonable budget

With engineers rushing tests in order to hit tight product deadlines, the market for test equipment that automatically detects faults in semiconductors and other

With engineers rushing tests in order to hit tight product deadlines, the market for test equipment that automatically detects faults in semiconductors and other

Automated test equipment (ATE) is a computer-controlled test and measurement equipment that allows for testing with minimal human interaction. The tested devices are referred

“ReadyDAQ provides a customizable LabVIEW solution which is both time-saving and affordable”.

The team – ReadyDAQ has a dedicated team of physicists, electrical engineers, and programmers who work to provide a data acquisition solution for any project in different difficulty levels.

Address: Matam – Scientific Industrial park, Building 30, Haifa, Israel

Phone: +972 72 250 5555

Mail: info@ReadyDAQ.com