Description

Introduction: before releasing a product to the market, a performance validation must be conducted to evaluate the real performance of the device for regulation uses (such as FDA or CE approval) as well as for marketing proposals to assure that the competitive advance of the product is a few steps ahead of the competitor devices.

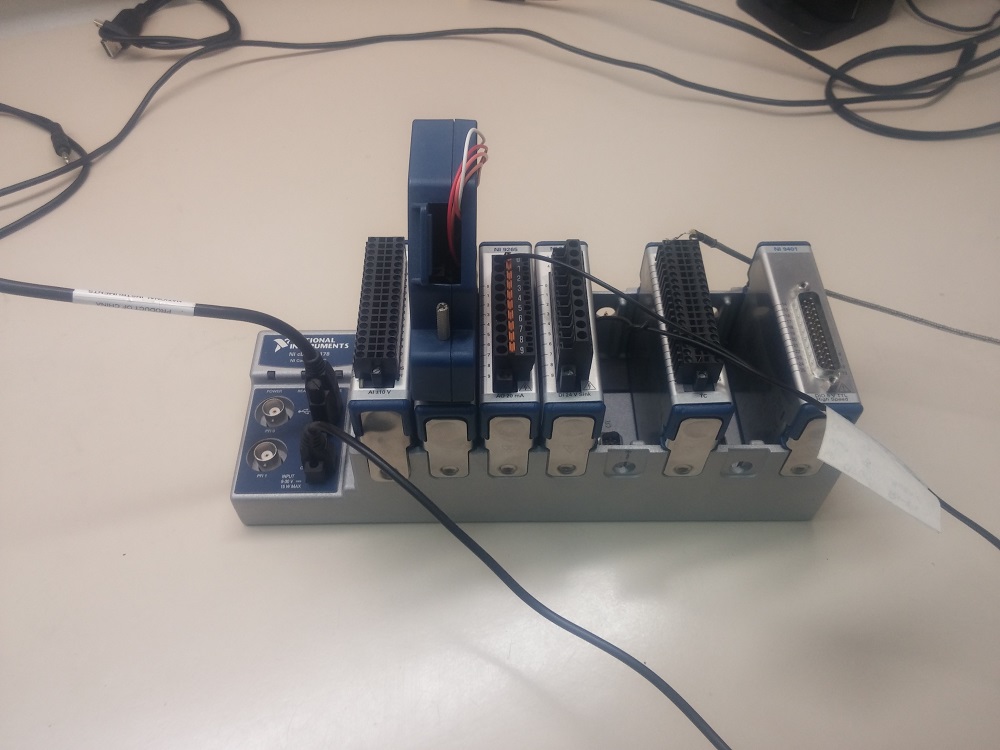

In this project an NI USB-6343 was used in order to develop a product lifetime setup during the development of an aesthetic device.

The NI USB-6343 includes a variety of BNC connectivity and OEM options that was convenient to our customers.

The device also included:

• 32 analog inputs

• 4 analog outputs

• 48 digital I/O lines

• Four 32-bit counter/timers

The project required a sequential process in order to simulate the full operation of the device, including moving the instruments, operating the product in different setting points, measuring signals from external measurement devices, logging all data to a data logger file, and repeating the sequence continuously.

Inside the product, a few sensors ware fed into the analog and digital input channels such as strain gauges, photodiodes, current meters, voltage meters, energy meters and switch outputs. These sensors were used to control the product output and to see the variations as a function during the lifetime tests. The control of the switches was done for investigation in case of failures to understand the causes of the mishaps.

In additional a lot of other sensors were used to monitor the system externally: temperature sensors were connected to different test points on the system’s PCB and velocity sensors were used to check the moving parts of the system, i.e. arms that were connected to scanners.

Similarly, for the analog and digital outputs, some of them were used for the automatic operation of the device, while others we used for the external environment, to simulate the product operator (i.e. to simulate the physician). Among this, the external setup included scanners that held and moved an arm as well as a hand-piece.

All measurements as well as operation modes were logged in to a log file.

ReadyDAQ customized the order to meet the customer’s requirements, and since the software application was not built from scratch the software was delivered very fast and in a reasonable budget

- Date Published: 06/22/2016

- Categories: Computerized control and command software setup utilizing LabVIEW

Example projects

Developing a Product Lifetime Setup for an Aesthetic Device

Computerized control and command software setup utilizing LabVIEW

Developing a Product Lifetime Setup for an Aesthetic Device

Computerized control and command software setup utilizing LabVIEW

Developing a Prototype to Operate a Carbon Fiber Based Heater

Computerized control and command software setup utilizing LabVIEW